GUP ROLLER SERIES

With over 12million units sold globally, the GUP Series is our most popular roller offering the best value for money in light and medium bulk materials handling.

We’ve been manufacturing GUP rollers since 1980, using a fully automated production line that guarantees GURTEC’s German engineering quality in every roller, with the shortest lead times in the market.

Premium Sealing

Fitted with our in-house manufactured 3-piece labyrinth sealing system, the GUP series includes all GURTEC standard design features.

Assured Quality

The GUP production process is fully automated using the highest technical manufacturing standards to ensure quality in every roller.

Welded End Cap

Robust, fully welded end caps are integrated into the GUP Rollers, creating a dust and waterproof seal.

Applications

Light Duty

Tunneling

Process Industry

Our Products

UNIT HANDLING ROLLERS

- Used for heavy unit goods conveyors

- Chain-driven and non-chain-driven

STANDARD END CAP ROLLERS

- Steel rollers for harsh environments

- Effective labyrinth seals and bearings

IMPACT ROLLERS

- Impact rollers are available with rubber or polyurethane discs

- FRAS discs are available for explosive environments

DISC RETURN ROLLERS

- Support discs prevent build up on the roller and therefore help avoid accelerated belt wear

- Various profiles and arrangements are available to suit customer demands

MACHINED AND BALANCED ROLLERS

- Excellent roundness and balance reduces vibration and ensures quiet operation and extended roller life

ALUMINIUM END CAP ROLLERS

- Aluminium rollers are ideal for harsh corrosive environments

- The light weight also provides EHS benefits during installation and replacement

MOULDED END CAP ROLLERS

- The composite roller is up to 60% lighter than an equivalent steel roller

- Available with composite, aluminium and steel shell materials

- At R&D stage

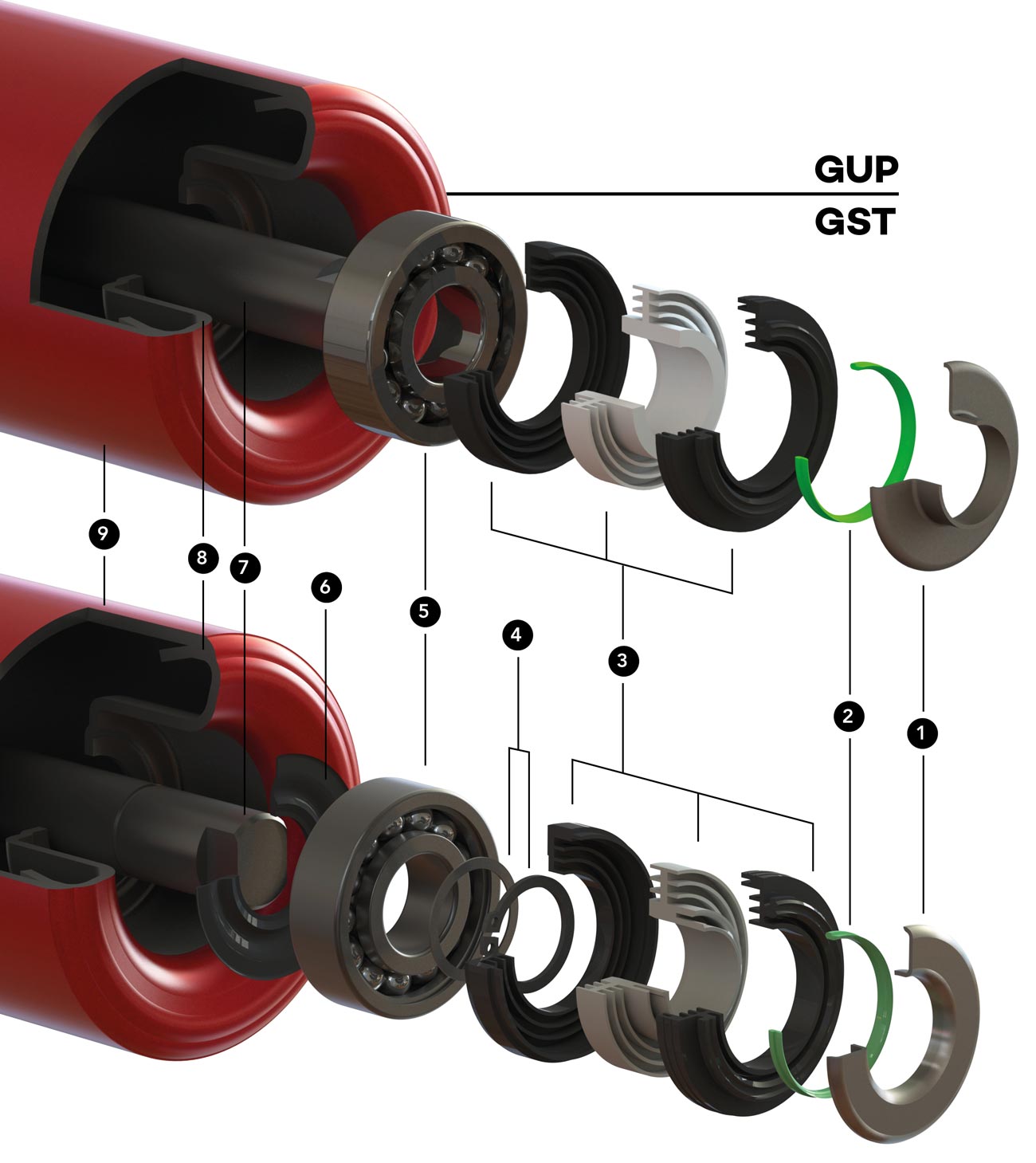

GUP/GST FEATURES

1 | DUST CAP AND SPLASH PROTECTION

2 | ADDITIONAL LIP SEAL

– optional

3 | 6-WAY LABYRINTH SEAL FROM OWN PRODUCTION

The smallest possible distance between the separate labyrinth channels and the perfectly dimensioned grease chamber guarantee a durable sealing system for all applications.

4 | SEALING RING AND WASHER (ONLY GST)

5 | DEEP GROOVE BALL BEARING

– clearance C4 with cage made of fiberglass reinforced polyamide 6.6

6 | REAR BEARING SEAL

(ONLY GST)

7 | SHAFT

– Availability of all shaft ends, shaft diameters 17-60 mm and reinforced shaft diameter between bearings.

8 | BEARING HOUSING

welded to the roller shell (dust- and waterproof)

9 | ROLLER TUBE

– welded special roller tube with tolerances exceeding DIN standards

9 | ROLLER SHELL

– blasted SA 2.5 and powder coated (RAL3000) with layer thickness of approximately 60 μm