GURTEC PREMIUM ROLLER

The GURTEC Premium Roller is setting a new standard for high speed mass transportation and life cycle costs.

Our highly automated manufacturing line utilises a flow forming process for extremely round tubes and an end forming process to round shell edges and integrate concentric bearing houses to the roller shell body, avoiding the need for welding.

Low Rotating Mass

The GPR combines lightweight bearing housings, a hollow shaft and highly concentric tubes to create a low overall mass.

Long Term Solution

Dynamically balanced for life, GPR rollers are proven to withstand high belt speeds over an extended lifetime.

Innovative Design

In-house manufacturing from GURTEC uses premium sealing arrangements designed to accommodate rough mining conditions & climates.

Applications

HEAVY DUTY

MINING

LONG DISTANCE

Our Products

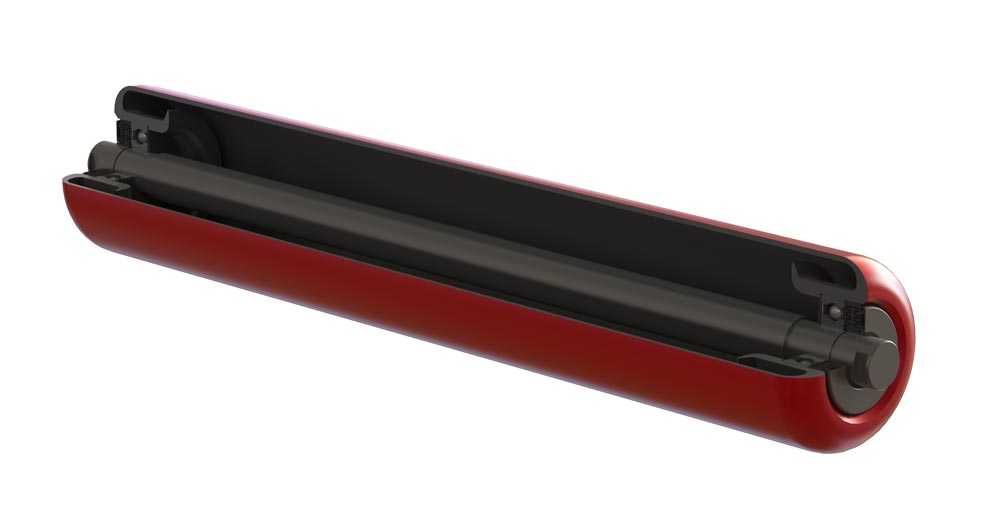

END FORMED ROLLERS

A roller with a solid shaft as standard, hollow shaft as option Bearing seats formed as an integral part of the shell, the opposing bearings are therefore accurately aligned The formed bearing holders improve bearing performance leading to lower failure rates Dimensions: Roller diameters 152 – 219 mm (6” to 8-5/8”) Shaft diameters up to

FLOW AND END FORMED ROLLERS

A flow formed roller shell and hollow formed shaft Option for an increased wall thickness at the middle of the shell for reduced shell deformation and increased fatigue life Extremely low TIR with a accurate and constant shell thickness significantly reduces vibration and increases service life Dimensions: Roller diameters 159 – 219 mm (6-1/4” to

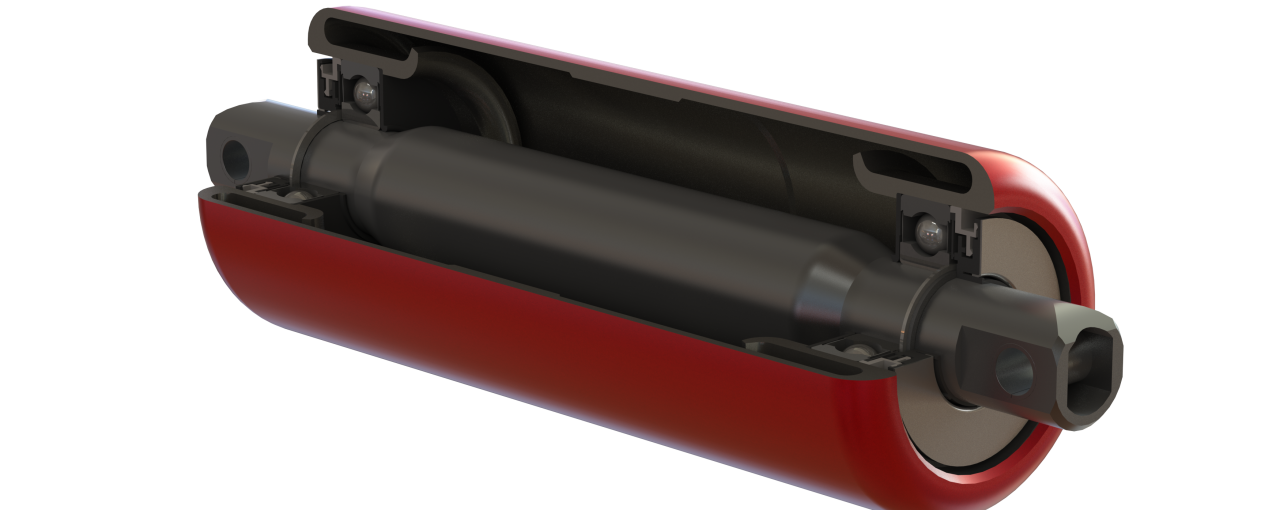

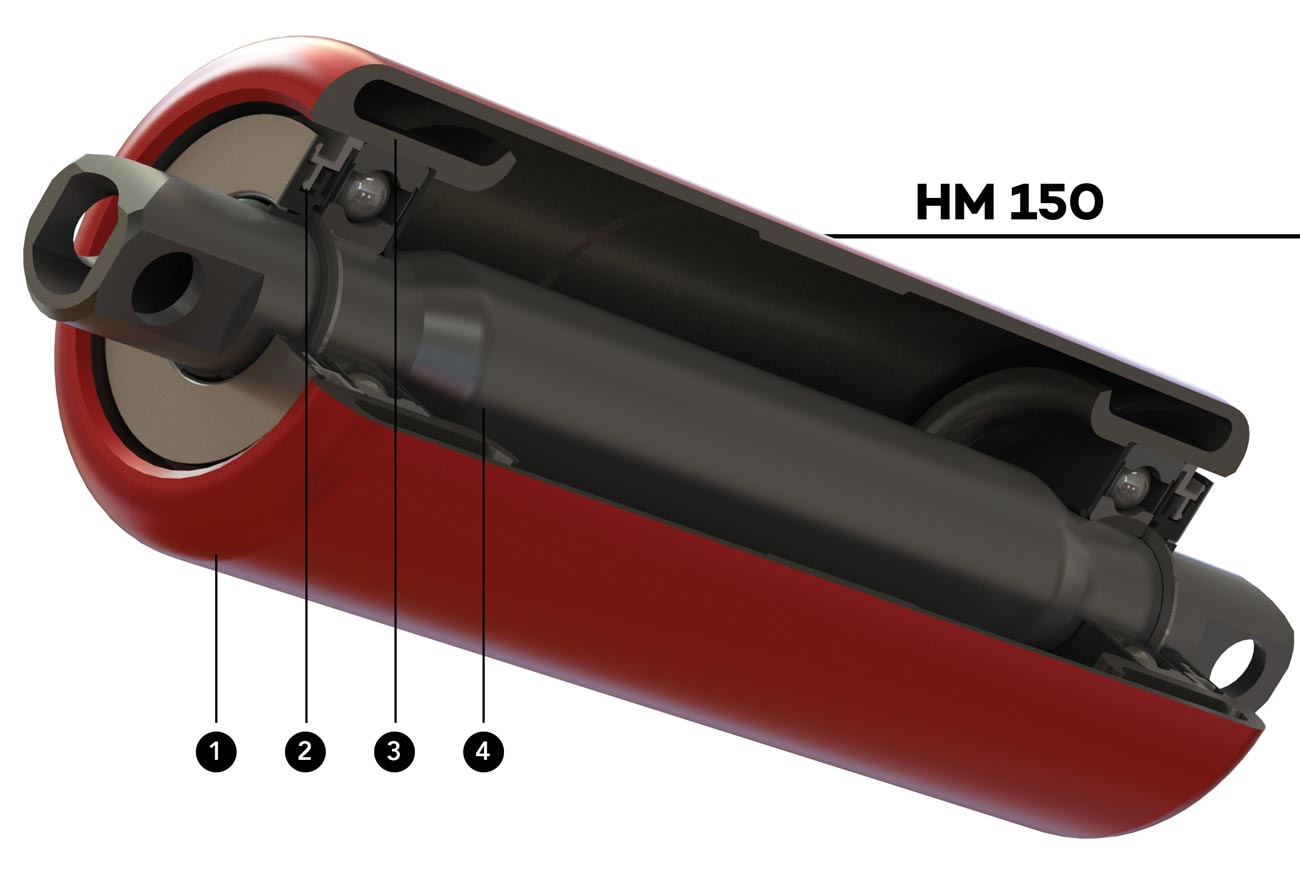

1 FLOW-FORMED ROLLER TUBE

Excellent balancing quality (<0.3. Due to the tube forming process, there is no need for dynamic balancing and machining. This allows high belt speeds and increased capacity while decreasing noise emission. The solidifi ed surface of the roller shell leads to reduced wearing of the tube.

3 INTEGRATED BEARING SEATS BY END-FORMING

The tube ends are formed into bearing housings. This means that no separate bearing housings and welding are needed. Belt friendly – no sharp edges.

2 MULTI-CHANNEL LABYRINTH SEAL FROM OWN PRODUCTION

effectively keeps dirt, dust and moisture away from the bearing – increases bearing life.

4 COLD-FORGED HIGH-PRECISION HOLLOW SHAFT

instead of a solid steel shaft, which reduces weight and cost while also giving less deflection.